Design of reverse osmosis systems for industrial and civil waste water treatment.

REVERSE OSMOSIS – HOW IT WORKS

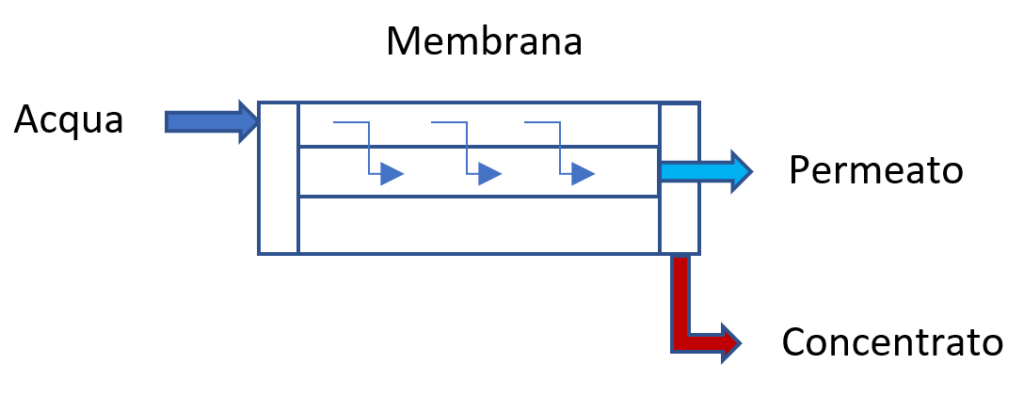

The water containing dissolved salts and contaminants is pushed through pumps inside semi-permeable membranes at a pressure that overcomes the osmotic pressure.

The initial flow of water is thus broken down into two flows: concentrate and permeate, the concentrate is the waste from the process, in fact in this flow there is a greater concentration of salts and contaminants; the permeate is purified water.

The heart of the process are the semi-permeable membranes, so called because they can be crossed by molecules with certain dimensions, the material of the membranes used in reverse osmosis can be: polyamide (TFPA, PA), PET, PVC, ceramic. The smaller the pores of the membranes the greater the degree of filtration, depending on the size of the pores we distinguish:

- REVERSE OSMOSIS 0.0001 micron

- NANOFILTRATION 0.001 micron

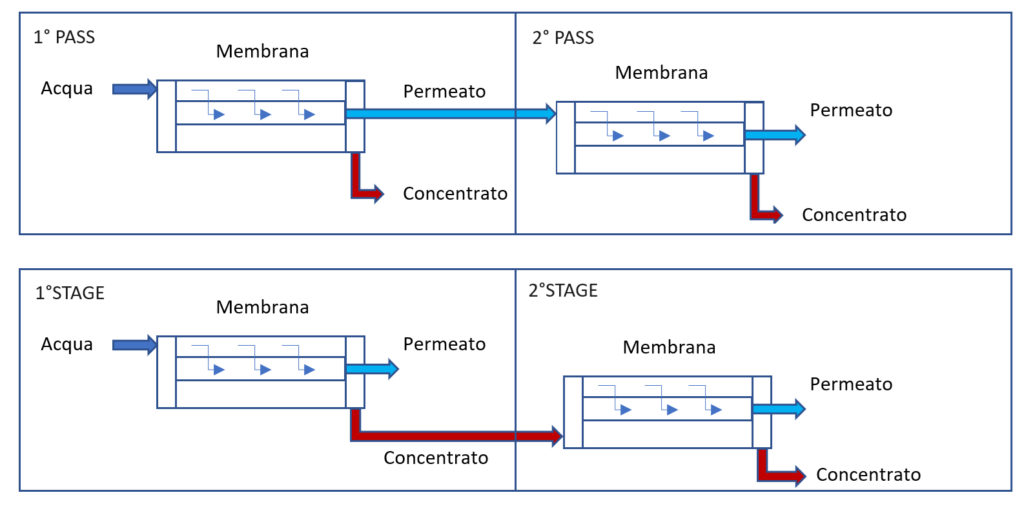

Two fundamental concepts in reverse osmosis are the pass and the stage. When we use the permeate of the first membrane to feed the second we create a two-pass process. Conversely, if we use the concentrate from the first membrane to feed the second, we create a two-stage process.

In general, the greater the number of passes, the greater the degree of filtration, but at the same time the lower the permeate flow rate. If the number of stages is increased, the greater the flow rate of recovered water will be. By combining these two concepts it is possible to create multiple combinations of passes and stages.

WATER REVERSE OSMOSIS SYSTEM